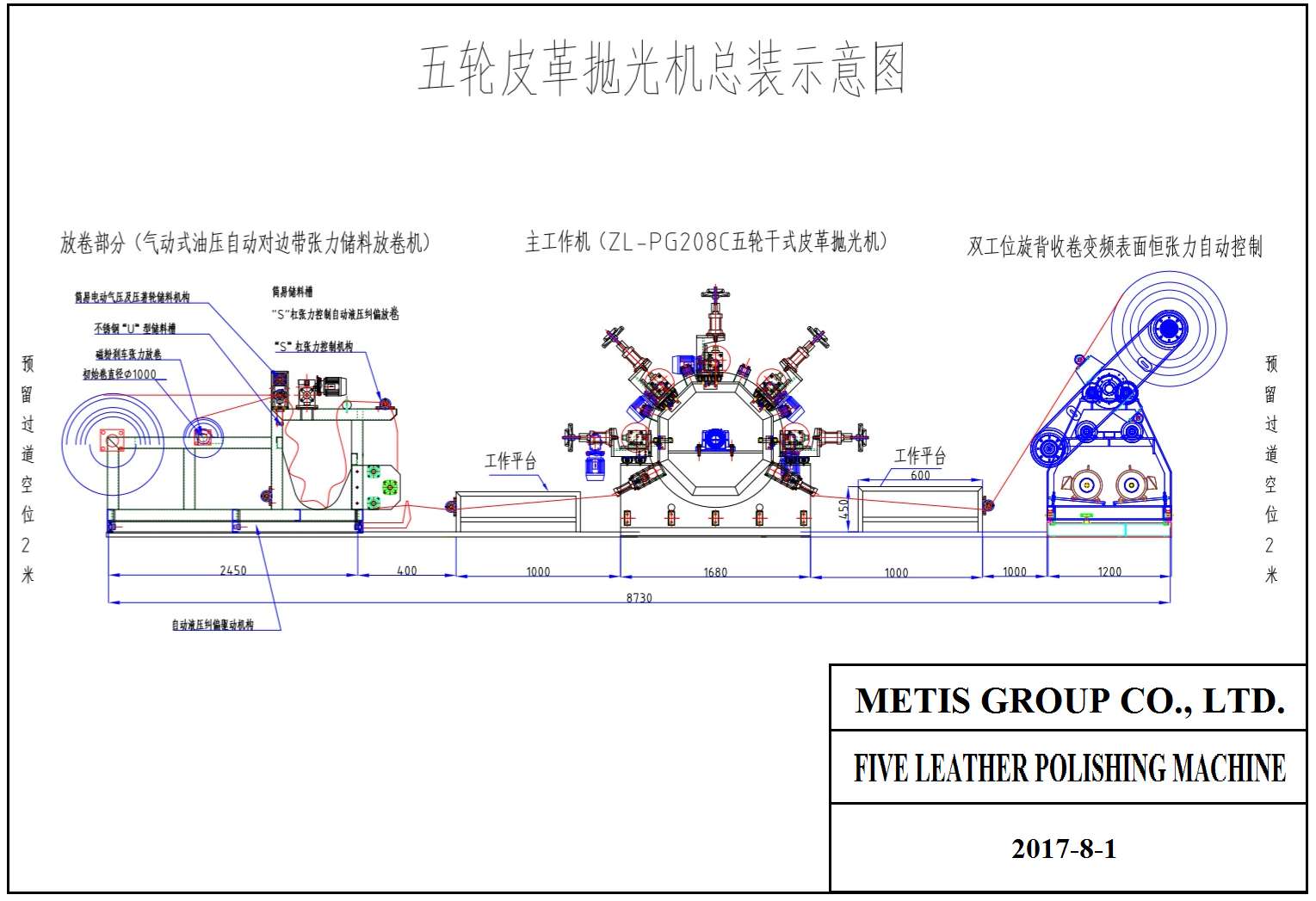

DSPECIFICATION

1. Dimension (LxWxH) : 8.73x4.6x2.3

2. Power : 72KW

3. Voltage : AC380

4. Effective working roller width : 1650mm

5. Speed : 0-42m/min

A. Unwinding Part

1. Rack with 10 # high quality channel and 100X100 square steel welding, Bottom 3mm anti-skid plate,

2. Double position big&small unwinding design

3. Unwinding with 5KG electronic magnetic powder tension controller +

Magnetic powder brake shells tension-unwinding....................................................................................................................1SET

4. Convenient pneumatic crimping wheel + AC motor quick storage mechanism +

Stainless steel "U" slot storage tank..................................................................................................................................................1SET

5. Storage tank outlet with Simple "S" tension bars.................................................................................................................1PAIR

6. 2HP hydraulic EPC correction system..........................................................................................................................................1SET

7. ∮88 electroplating wheel or aluminum alloy guiding wheel......................................................2PIECES

8. ∮125 silicon wheel.........................................................................................................................................1PIECE

9. ∮125 electroplating wheel...........................................................................................................................1PIECE

B. Polishing wheel entrance Operation pedal

1. Operation pedal made of 10# high quality channel welding

2. ∮88 electroplating wheel (or aluminum alloy guide wheel)........................................................................................2PIECES

C. Machine part

1. The rack is made of high quality 120X80 flat pass and high quality thick walled steel welded together (with drawings)

2. The connection part is welded for high quality channel connection. Portion reinforced ribbed plate welding.

3. The various parts of the flap protective cover according to the overall design of

4. Main drive wheel is ∮ 1200 after finishing the grinding roller

5. Siemens 11KW horizontal AC motor (control 5 sets of polishing wheel)...................................................................5SETS

6. Siemens 1.5KW horizontal AC motor (Control main drive wheel)..................................................................................1SET

7. ∮ 280 easy to replace the polishing wheel..........................................................................................................................5PIECES

8. Universal joint....................................................................................................................................................................................5SETS

9. ABB linear guiding roller.............................................................................................................................................................5PAIRS

10. Pneumatic crimping system....................................................................................................................................................10SETS

11. ∮ 130 pressed silicon roller.......................................................................................................................................................1PIECE

12. Raised type horizontal electric large reduction ratio swing mechanism.................................................................5SETS

13. Dust collect device (Including power, fan, dust belt).........................................................................................................1SET

D. Polishing roller entrance operating pedal

MACHINE DRAWING